A brand of LIANSU, Mconvey provides one-stop automated material handling solutions for the plastics industry. Hereunder we will introduce automated granular material handling solutions to you. It can improve production efficiency, ensure accurate proportioning, reduce waste and labor costs, optimize inventory management, and improve product quality stability by automated debagging, storage, weighing, dosing, mixing, dehumidification and drying, conveying and control. It helps users achieve efficient production and cost control. At present, it has been successfully applied in plastic industries such as injection molding, blow molding, film production and plastic compound extrusion.

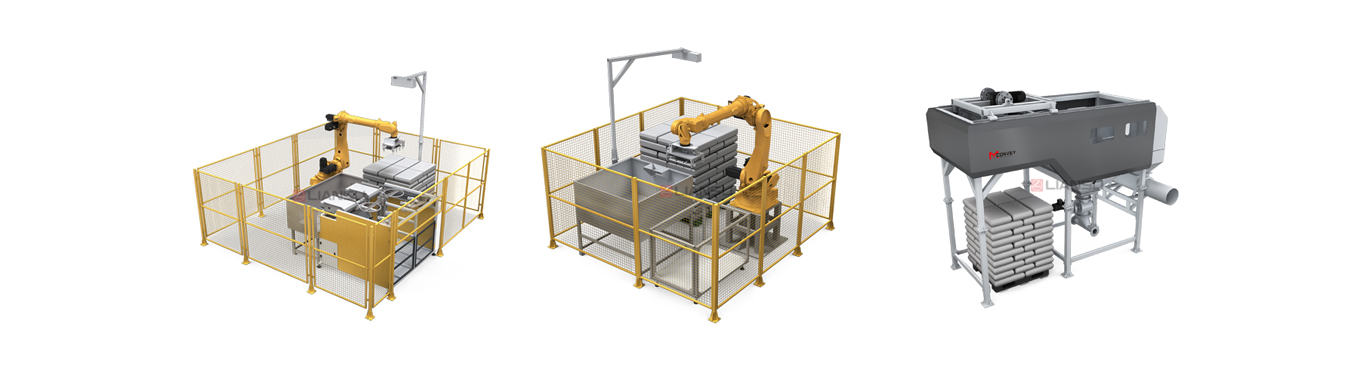

Debagging

The fully automatic robot debagging station can handle granular materials in 25kg packaging bags. It can automatically complete the material debagging and feeding, improve material conveying efficiency, reduce manual operations, and ensure the accurate supply of raw materials.

Silo

Mconvey offer different type of silo to different needs, metal material like 304 stainless and Magnesium aluminum alloy silo, also Fabric silo, silo construction Mconvey offer bolt-type and welded. currently we offer max capacity of 400 cubic meters. The silo is fabricated with robot welding workstation to ensure that even, firm, and durable welding.

Dosing and Mixing

According to customer needs, Mconvey provides a variety of dosing and mixing solutions to ensure accurate and efficient material metering, improve production efficiency and product quality. For adding masterbatch, we provide efficient gravimetric doser for granular material. For the dosing and mixing of various granular materials, we provide accurate multi-component gravimetric blender. For powder and granular mixing, we provide automatic formula weigher. At the same time, we provide online multi-granular material loss-in-weight feeder specifically for the membrane industry.

Dehumidification

The insulation dryer and dehumidification dryer can effectively remove moisture from plastic particles, ensure that the material remains in the best dry state, and improve the quality of product molding and appearance. Among them, the dehumidification dryer integrates multiple functions and it is more efficient and energy-saving, and saves more space.

Conveying

Permanent magnetic vacuum pumps are used for vacuum conveying. A single set of pumps replaces multiple sets of traditional Roots pumps. An intelligent centralized dust collector is used to achieve efficient and energy-saving material conveying. The system has low temperature and low noise, and is equipped with intelligent monitoring to ensure stable operation and optimized management.

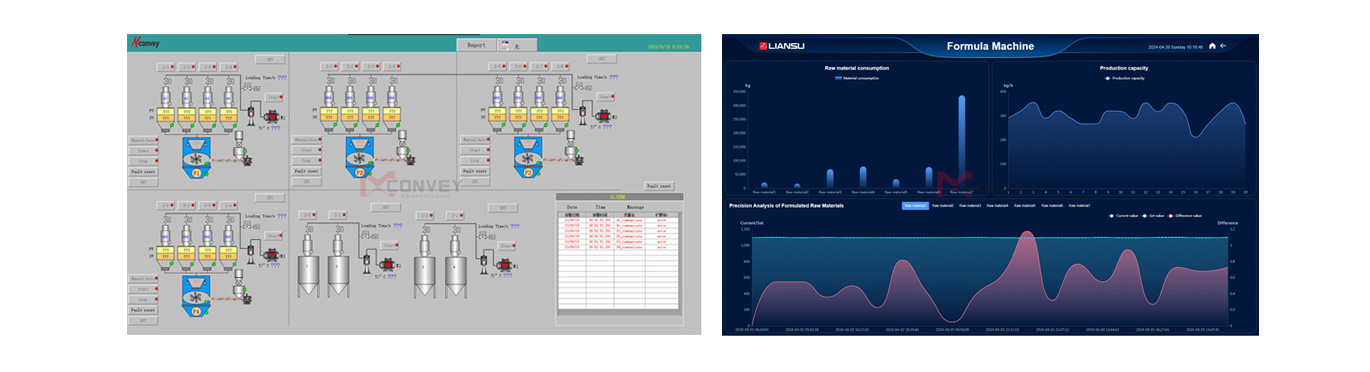

Control

The SCADA system provides customers with comprehensive material handling process monitoring and control to ensure accurate production management. The system can be equipped with an IoT information management system, which connects equipment, sensors and controllers to the Internet to achieve equipment digitization, real-time data collection and analysis, achieving comprehensive visualization and intelligent management of the production process.