A brand of LIANSU, Mconvey provides a one-stop automated material handling system for different type of powder materials to optimize material handling and improve production efficiency. The system integrates the parts of debagging, storage, weighing, mixing, conveying, and control to achieve high-precision material management reduce manual intervention and labor costs, and improve product quality, realized automated and efficient production.

Mconvey system is applicable in different kinds of powder materials, including PVC resin, calcium carbonate, titanium dioxide, pigment, flour, salt, silicon dioxide and other materials to meet different production needs. At present, Mconvey has successfully established different cases and solutions in the industry of plastic pipe, profile, plastic sheet film extrusion and compound pelletizing at home and abroad.

Debagging

Provide automated material debagging system and jumbo bag discharging station to reduce labor intensity and labor costs, reduce dust pollution and improve efficiency.

Silo

Mconvey offer different type of silo to different needs, metal material like 304 stainless and Magnesium aluminum alloy silo, also Fabric silo, silo construction Mconvey offer bolt-type and welded. Currently we offer max capacity of 400 cubic meters. The silo is fabricated with robot welding workstation to ensure that even, firm, and durable welding.

Weighing and mixing

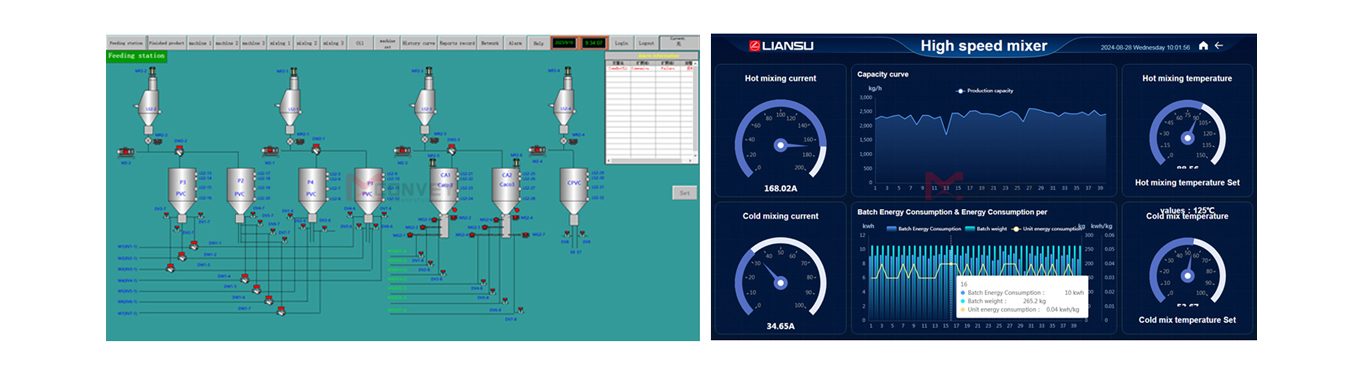

Different weighing equipment is matched for the main materials and small proportion formula materials. Mconvey provides multi-component powder formula weigher, loss-in-weight feeder, loss-in-weight formula weigher, pigment doser for accurate weigh of powders and additives, realizing multi-component batch weighing, ensuring accurate proportions of materials, and providing guarantees for subsequent production. In addition, "High-speed mixer" and "Ribbon mixer" or "Horizontal coulter mixer"can be selected to mix materials and avoid problems such as stratification and uneven mixing. The weighing and mixing data are traceable, and real-time data on energy consumption and material consumption can be displayed and analyzed.

Conveying

According to the physical properties and fluidity of different materials, the system provides a variety of conveying methods to ensure the smooth flow of materials, avoid blockage and stratification, and realize flexible online switching. In addition, the patented permanent magnetic vacuum pump group can greatly reduce the energy consumption of material conveying, intelligently distribute the load, and improve the reliability and environmental protection of material conveying.

Control

The control system is equipped with SCADA system , and can be equipped with the loT System, which provides monitoring and control of material handling process. The "IoT information management system" can be optionally configured according to the users to achieve visual monitoring and traceability of production process data, as well as equipment maintenance, material consumption and energy consumption data analysis dashboards and other functions.