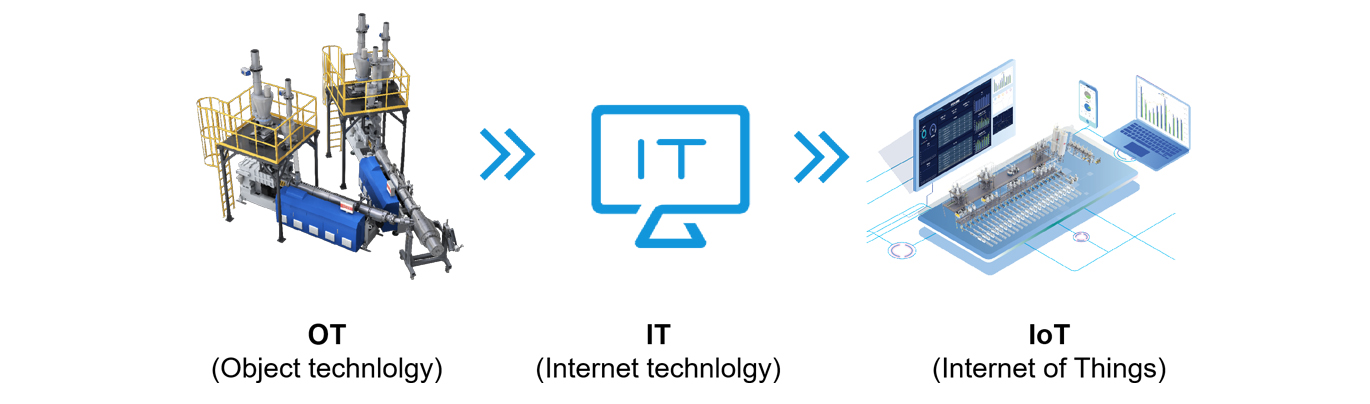

As a leading manufacturer of automated plastic extrusion production line , automated material handling systems and automatic packaging equipment, LIANSU has always been committed to providing customers with efficient and intelligent solutions. Our independently developed intelligent IoT data acquisition and analysis system aims to help customers achieve comprehensive digital management of prodction equipment through IoT technology, improve production efficiency, reduce operating costs and optimize production processes.

Introduction

Liansu IoT data collection and analysis system is an industrial data collection, transmission, storage, analysis and visualization platform based on IoT technology. It can seamlessly connect your plastic extrusion production line, material handling system and auxiliary equipment, collect equipment operation data, production data, energy consumption data, etc. in real time, and provide data support for your equipment status monitoring, production efficiency analysis, fault prediction and early warning, energy management optimization and other all-round decision-making services through a powerful data analysis engine, helping you realize the digitalization, networking and intelligence of the production process.

Features

Real-time data collection and equipment monitoring

·Through sensors and edge computing devices, key data such as equipment operating status, temperature, pressure, energy consumption, etc. are collected in real time.

·Provide a visual dashboard to monitor equipment operation in real time to ensure transparency and controllability of the production process.

Equipment health management

·Provide equipment maintenance plans and reminders to extend equipment life and reduce maintenance costs.

·Analyze equipment operation data, predict potential failures, issue early warnings, and reduce downtime.

Production management and efficiency improvement

Real-time collection of production data, equipment status, etc., follow up on production progress, analyze equipment utilization, optimize equipment operating parameters, and improve production efficiency.

Quality management and analysis

Real-time collection of parameter data related to product quality during the production process and analysis to help you promptly identify quality problems, trace the root causes of problems, optimize production processes, and improve product quality.

Energy consumption management and environmental optimization

·Real-time monitoring of equipment energy consumption, identification of high energy consumption links, and providing data basis for energy saving and cost reduction.

·Support environmental data collection to help customers achieve green production and reduce carbon emissions.

Data visualization dashboard

Provide an intuitive and easy-to-understand data dashboard to monitor equipment operating status, production progress, maintenance reminders, energy consumption, etc. in real time, so that you can see the production situation at a glance.

Advantages

Application

·Plastic extrusion production line: real-time monitoring of extruder operation status, optimization of production parameters, and improvement of product quality.

·Automatic material handling system: it ensure stable operation of the feeding system, reduce raw material waste, and improve production efficiency.

·Material handling auxiliary equipment: monitor the operation of packaging equipment, track product production progress in real time, and improve delivery accuracy.

Customer Value