LIANSU has developed, designed and produced a variety of telecommunication duct extrusion lines and has successfully delivered more than 30 projects,including corrugated optical duct (COD) and microduct tube bundle production line.

Size range(mm):

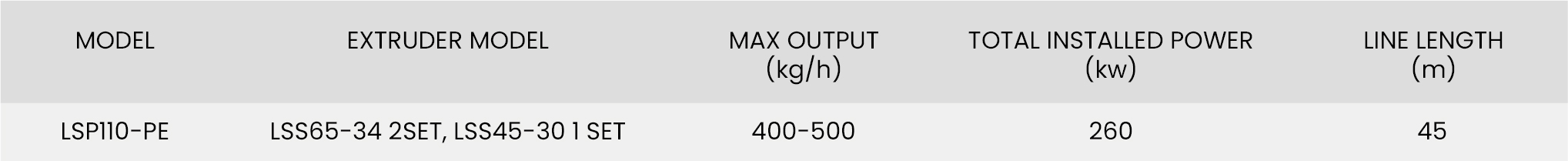

Max output(kg/h):