The production capacity can reach 1.3 tons/hour and 33 tons/day.It can realize online adjustment of formula, online dosing of calcium carbonate, abrasive material and pigment.It can realize online swarfless cutting of pipes of different lengths, online socketing of pipes of different lengths and online rubber ring installation.

Size range(mm)

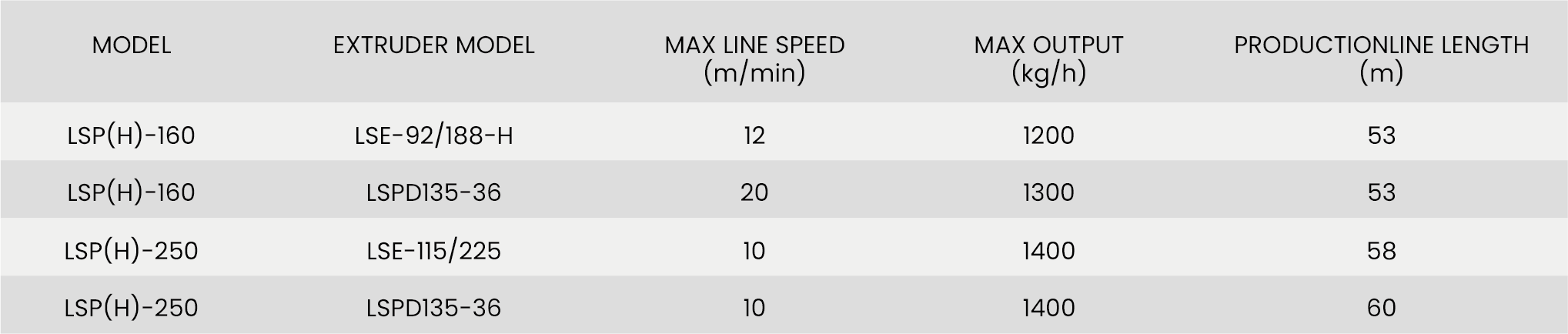

Output(kg/h):

Material: