This production line utilizes advanced single-layer or multi-layer extrusion technology, ensuring the pipes have excellent resistance to high temperatures, impact, and flexibility. Equipped with efficient extrusion equipment, precise cooling systems, and intelligent control systems, it guarantees high production efficiency and stable product quality. The production line supports the manufacturing of PERT pipes in various specifications and wall thicknesses, with easy operation and a high level of automation, meeting the piping needs of residential, commercial, and industrial buildings. extruder, pipe head,vacuum forming tank, haul-off unit and cutting machine.

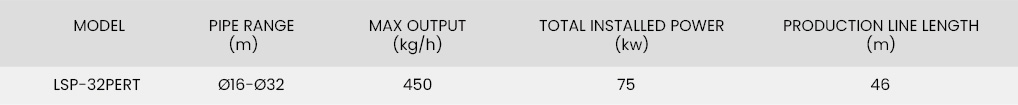

Size range(mm):

Output(kg/h):

Line speed(m/min)