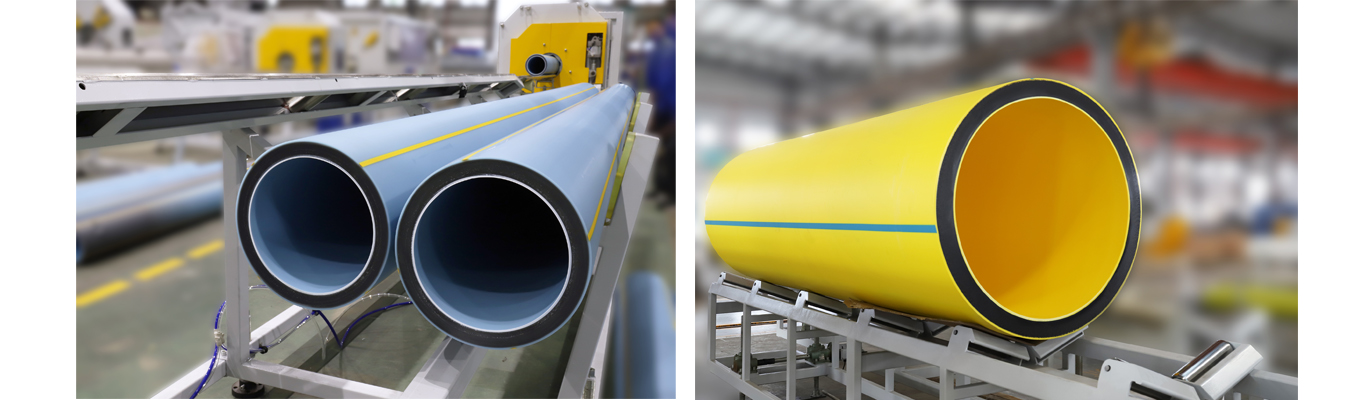

Multi layer HDPE pipe is mainly application in pressure water pipe. Multi-layer pipe with higher performance of physical properties is widely used in full range of pressure pipe system. LIANSU offers the size range from 20 to 2000mm with different models, ABA or ABC structure pipe line, with self developed closed extrusion system from extruder to weighing stacker and realizes automatic, accuracy , high efficiency production.

Size range(mm):

Output(kg/h):