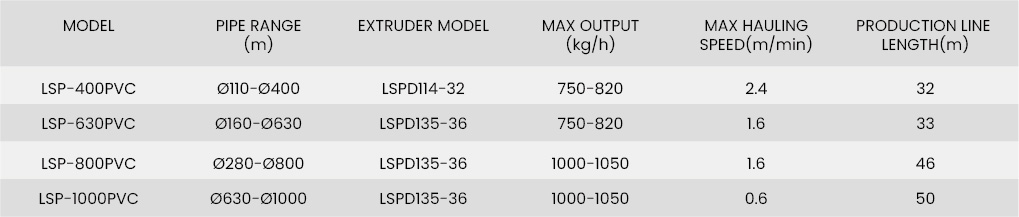

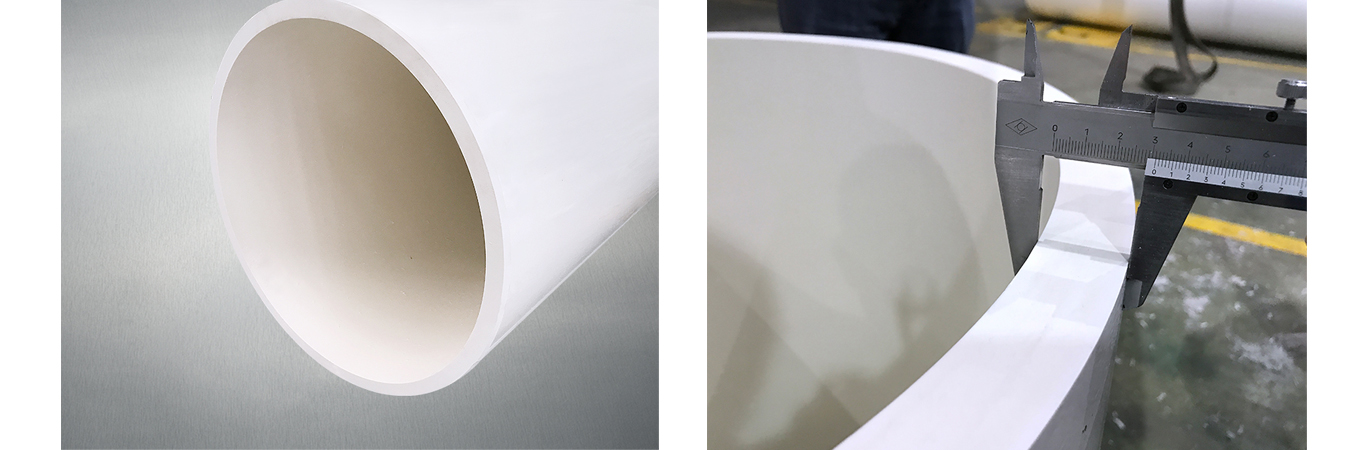

LIANSU offer wide range of PVC-U pipe line. Extruder equipped with large L/D ratio parallel twin-screw. Control system of completed line can choose self-developed FLEXCON system or traditional PLC control to realized different production management. The downstream line equipped can be equipted with on-line socket machine or on-line automatic packaging machine.

Size range(mm):

Output(kg/h):

Material: