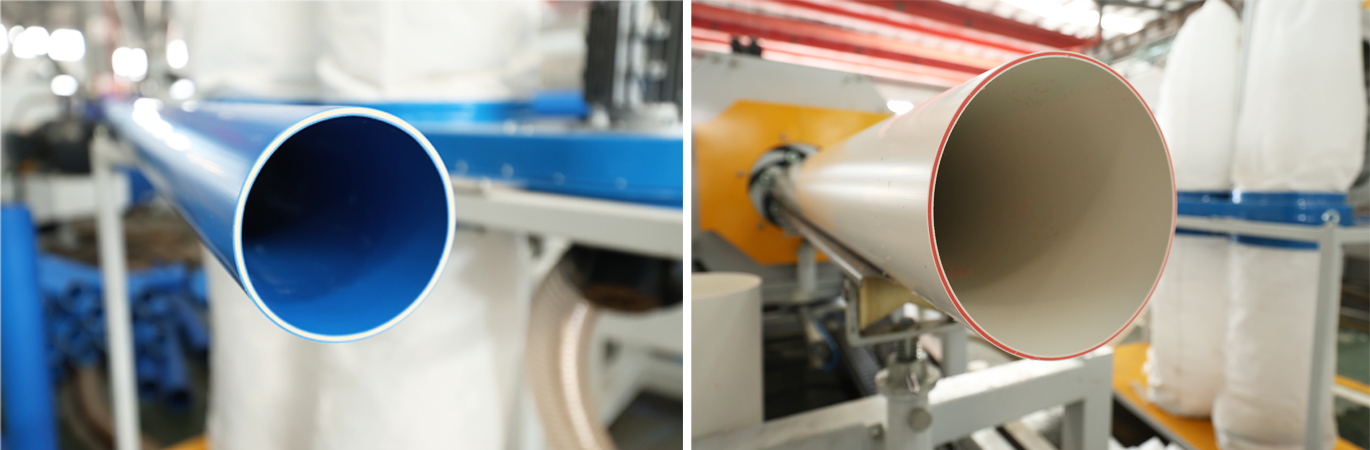

PVC Foam core pipe with ABA structure, external and internal is solid PVC, middle layer can be foam compound or recyled compound, main application in sewage pipe system with economic and noise reducing. Extruder can be parallel twin-screw or conical twin-screw extruder. Pipe head adopts LIANSU-PVC Foam pipe head and distributor, high output and stable temp. control. Control system of complete line can choose FLEXCON system or traditional PLC control to realized different production management. Downstream can be equipped with on-line socketing machine.

Pipe features:

Light Weight

Density: 1.0-1.2g/cm3Weight: 70%-85% of solid pipe

Low Cost

Same thickness ,material cost per meter isless than 10% of solid wall pipe

Less noise

Noise level reduced by 3 db

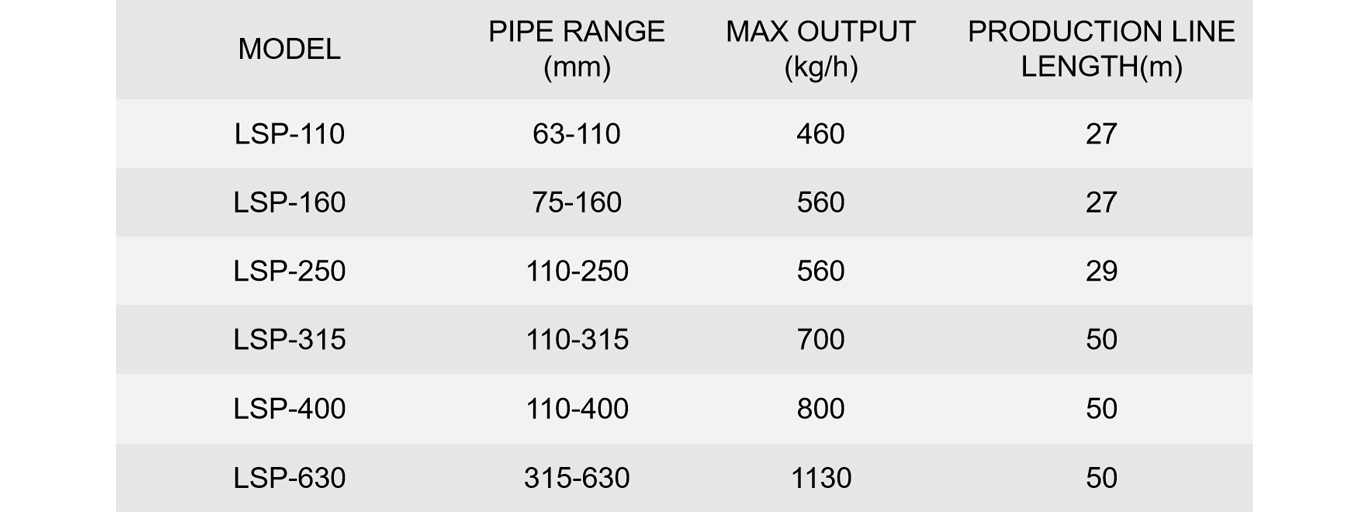

Size range(mm):

Output(kg/h):

Material: